VAUTID 70

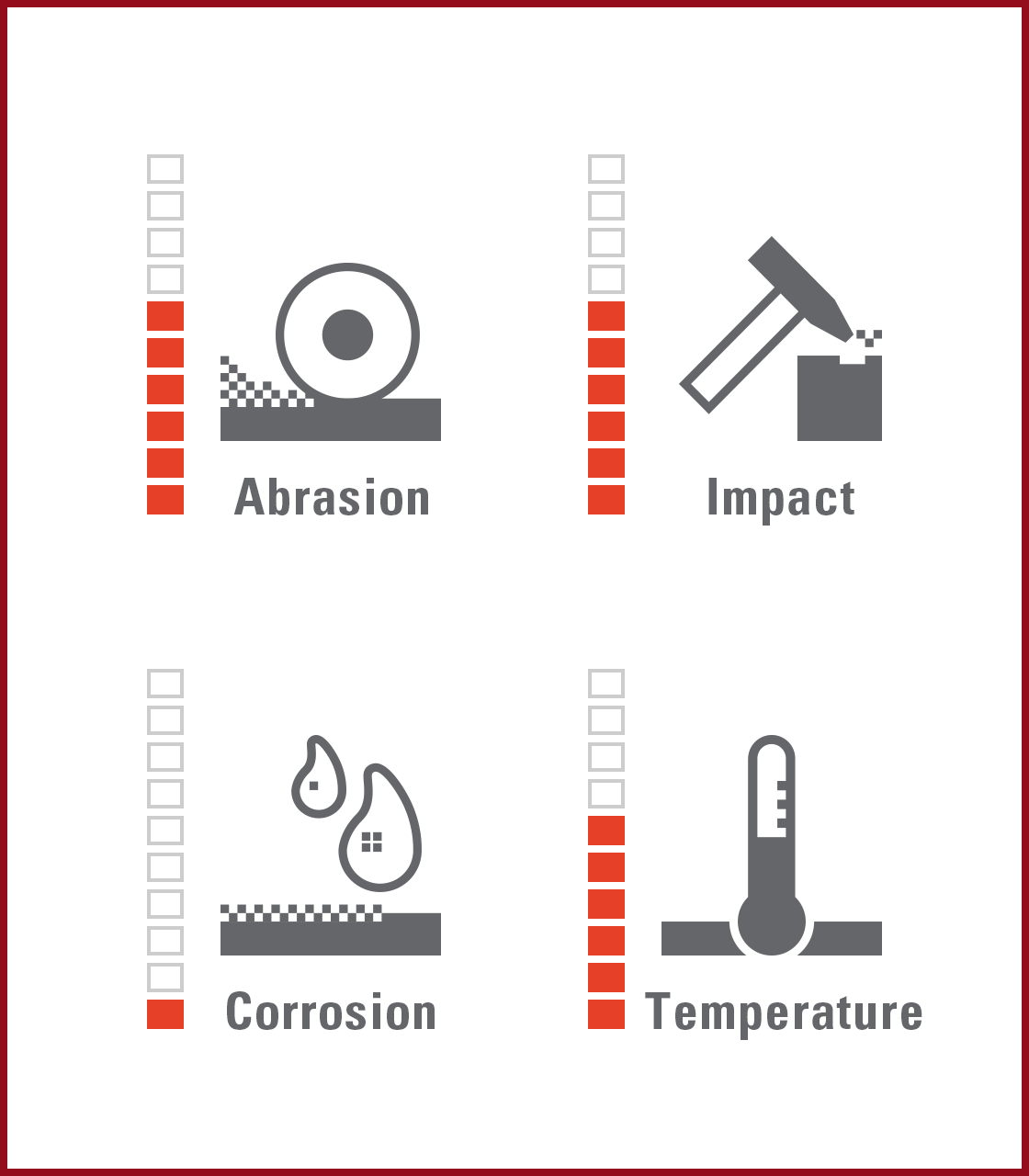

For tough, hard, heat-resistant overlays in applications where there is a combination of impact and abrasion

The metal used in VAUTID 70 contains titanium, which forms one of the hardest types of carbide in existence. Because of its titanium carbide content, this alloy offers excellent resistance to abrasive wear. The carbides of titanium are embedded in an extremely tough matrix. This provides particularly effective protection against impact. Furthermore, weld layers constructed from VAUTID 70 are crack-free and resistant to high temperatures.

Hence VAUTID 70 offers ideal wear protection for components which operate at elevated temperatures and are simultaneously subject to high levels of abrasion and impact.

Recommended applications:

- Components exposed to temperatures up to 670°C.

- Components which are subject to significant impact from abrasive materials,

e.g. deflector plates, blast furnace throat armor, funnels and chutes. - Moving components which operate in highly abrasive media and either strike solid bodies at high speed or experience extreme pressures within the media, e.g. high-pressure rollers, parts of crusher rolls, roller presses and hammers in hammer mills.

- Metal-on-metal wear applications, e.g. tools for hot forming or forging steel components.

Wear resistance

In abrasive applications, VAUTID 70 extends service life up to a factor of 6 compared to S235JR

Alloy

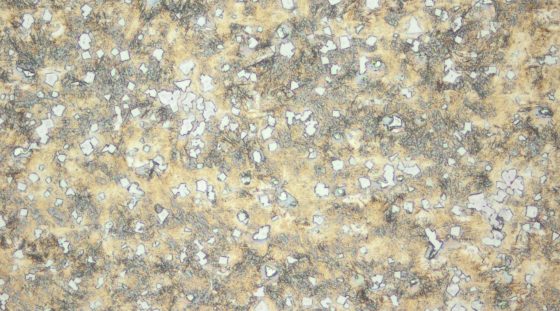

Carbides

Titanium carbides TiC 3200 HV1

Typical microstructure VAUTID 70

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).