VAUTID VVP 100T

For highly wear-resistant hardfacing at elevated temperatures

This composite wear plate comprises a base plate which has been overlaid, using a special metal arc welding process, with our highly abrasion-resistant and heat-resistant VAUTID 100T hardfacing welding consumable.

In our VAUTID 100T grade, wear absorption is provided by chrome carbides, embedded within an exceptionally stable matrix. This raised the maximum operating temperature of this protective alloy to 550°C.

Recommended applications:

- Components which are exposed to temperatures up to 550°C.

- To protect areas which carry a steady flow of abrasive media e.g. material slides, dust ducts, and separators.

- To protect components that operate in homogenous, abrasive materials, e.g. coking plant equipment, sinter crushers, clinker breakers, feeder screws, sieves and ventilator fans.

This welding alloy is also available as a VAUTID hardfacing welding consumable (VAUTID 100T).

Alloy

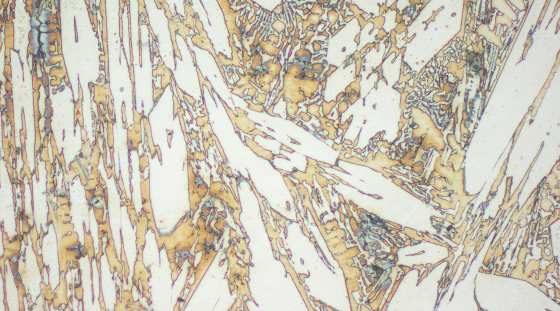

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID VVP 100T

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).