VAUTID W73

For components over 40 mm thick that are subject to impact and abrasion

This alloy is designed to provide maximum through-hardening on wall thicknesses above 40 mm. VAUTID W72 offers outstanding resistance against wear from abrasion and moderate impact. The wear-resistant properties of this material can be suspended by heat treatment. This is especially advantageous in the case of components that require machining.

Recommended applications:

- Cast components that are exposed to temperatures up to 400°C.

- Cast components that require machining.

- Components with wall thicknesses greater than 40 mm which are subject to abrasion and impact, e.g. hammers, plungers, agitators.

Mechanical properties

VAUTID use white cast iron materials produced to DIN EN 12513 grades GJN-HV520 – 5.5602 and GJN-HV600(XCr18) – 5.5609 for components exposed to abrasion or to a combination of abrasion and impact. Materials developed in-house by VAUTID are used in impact mills, crushers and conveyor units, commonly installed in recycling plants, asphalt works or power generation plants. Typical components include lining elements, mixer tools, pump parts, hammers and beater bars. VAUTID materials VAUTID W7, VAUTID W72 and VAUTID W72H can all be machined.

| VAUTID material | Tensile strengt [hN/mm²] | Crushing strenght [N/mm²] | Elastic modulus [kN/mm²] |

Hardness HB [HRC] |

Fracture toughness KIC [kN/mm²] |

| GJN-HV520 – 5.5602 (similar to Ni-Hard 1)1 |

– | – | – | approx. 52 | – |

| GJN-HV600(XCr18) – 5.5609 (similar to Ni-Hard 4)2 |

– | – | – | approx. 55 | – |

| VAUTID W31 | 450 – 800 | 620 – 750 | 165 – 180 | approx. 58 | – |

| VAUTID W41 | 450 – 800 | 620 – 750 | 165 – 180 | approx. 52 | – |

| VAUTID W73 | 600 – 1.000 | 2.800 – 3.200 | 158 – 190 | approx. 59 | 25 – 31 |

| VAUTID W723 | 600 – 1.000 | 2.800 – 3.200 | 158 – 190 | approx. 59 | 25 – 31 |

| VAUTID W72H3 | 600 – 1.000 | 2.800 – 3.200 | 158 – 190 | approx. 59 | 25 – 31 |

| VAUTID W733 | 600 – 1.000 | 2.800 – 3.200 | 158 – 190 | approx. 59 | 25 – 31 |

| VAUTID W78A3 | 600 – 1.000 | 2.800 – 3.200 | 158 – 190 | approx. 62 | – |

| VAUTID W1001 | 450 – 800 | 1.800 – 2.800 | 150 – 170 | approx. 59 | 25 – 31 |

Condition of delivery: 1 G; 2 G/hardened; 3 hardened

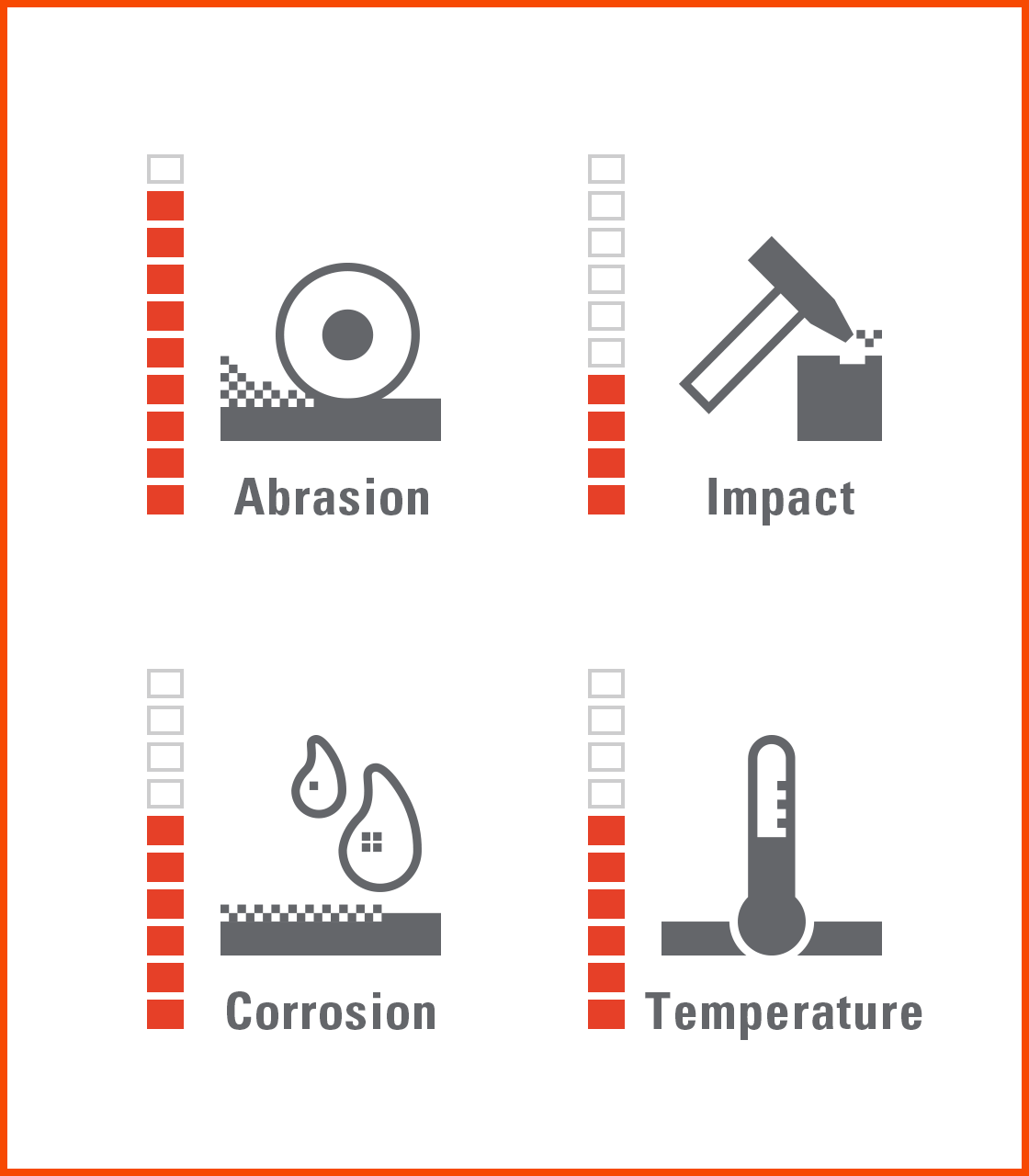

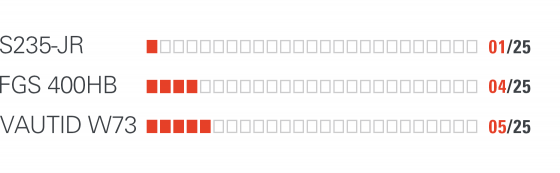

Wear resistance

In abrasive applications, VAUTID W73 extends service life up to a factor of 5 compared to S235JR

Alloy

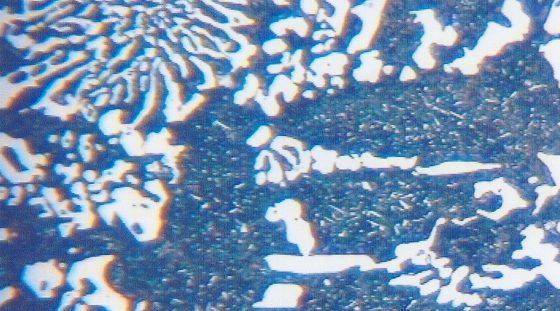

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID W73

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).