VAUTID Ultra 302

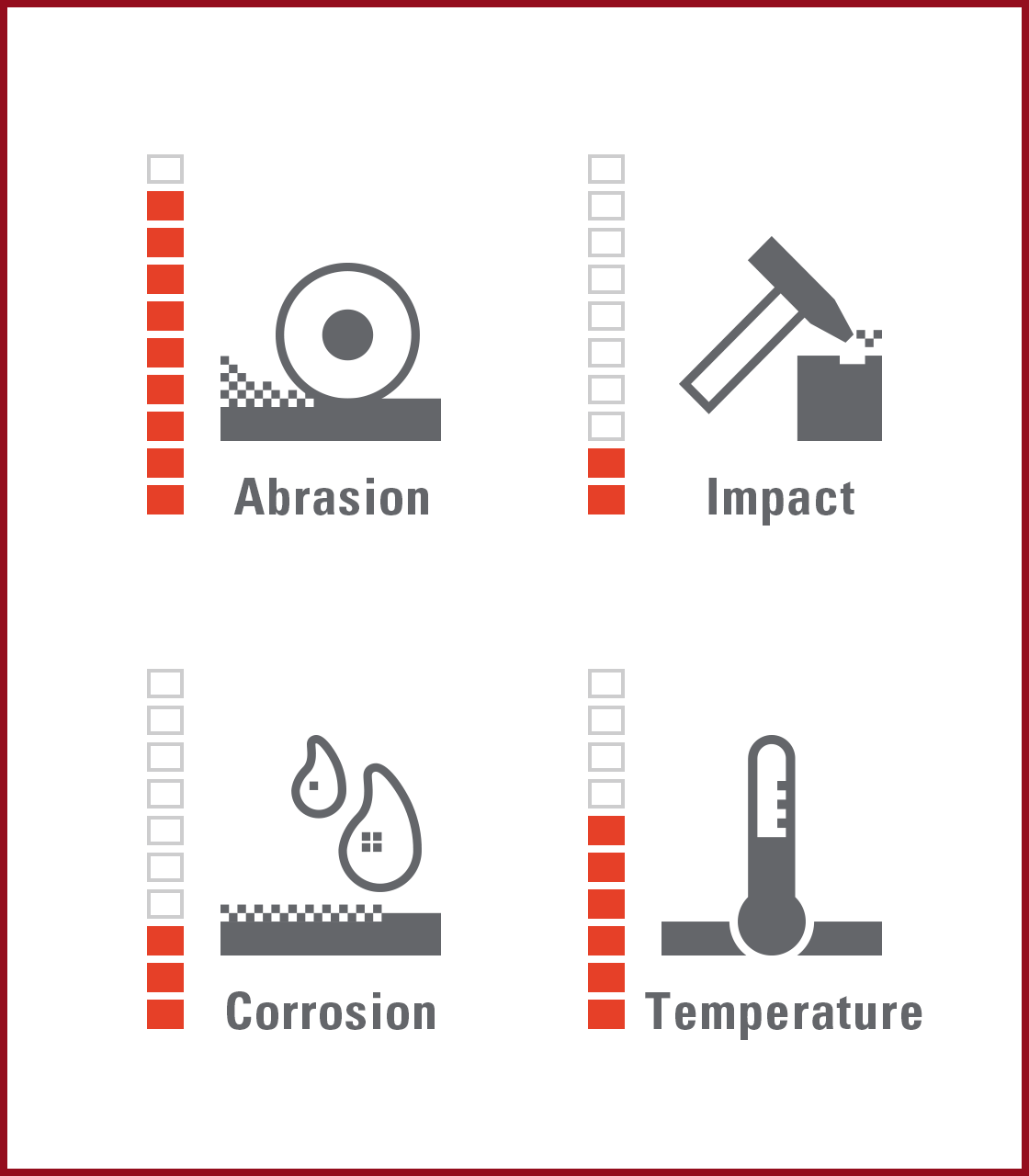

A hardfacing welding consumable in the form of an electrode rod for producing hardfacing layers with an exceptionally high level of wear resistance under low shock loading

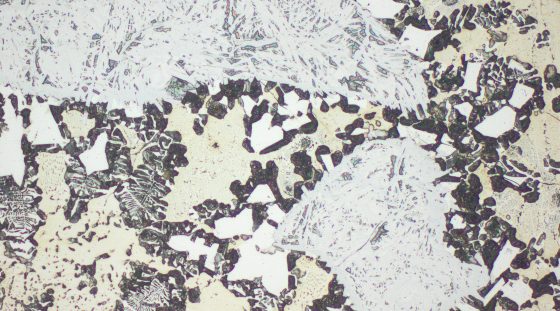

VAUTID Ultra 302 comprises a wear-resistant iron-based matrix containing unfused particles of extremely hard tungsten carbide. The carbide grains (sized 0.25 – 0.7 mm) are securely confined within the matrix, which retains its integrity when welded. This product can be used to produce multiple layers (three layers maximum).

Matrix hardness: ca. 700 – 900 HV10

Tungsten carbide: ca. 2000 HV10 (DIN 32525-4)

Recommended applications:

- Components subject to extreme abrasion, e.g. core bits, rolling cutter drill bits, deep hole boring bars, beater bars, ploughshares, grinding segments and scraper bars.

- For producing tough hard surfaces from multiple layers.

Alloy

Carbide

Tungsten carbides W2C3000 HV1

Typical microstructure VAUTID Ultra 302

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).