VAUTID 100Mo

For highly wear-resistant hardfacing, even with a low level of impact

VAUTID 100Mo is a variant of our well-proven VAUTID 100 specification. In addition to carbides of chrome, this welding material incorporates finely distributed special carbides, which increase resistance against abrasion wear. In addition, because of a specific adjustment to the formulation, VAUTID 100Mo has a finer gain structure than VAUTID 100. As a result, this weld material responds more flexibly to shock loads. This improves wear resistance under light impact conditions.

VAUTID 100Mo is therefore best suited for overlays on components which are subjected to high levels of abrasion and moderate impact loads.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- Components which carry a steady flow of abrasive media and are also subject to light impact, e.g. chutes and material slides onto which bulk material of a medium particle size falls and slides, and grinding tables in vertical mills where the material being milled contains even larger objects.

- Moving components which operate in homogenous abrasive media and strike solid bodies at moderate speeds, e.g. rollers and wear liners operating in very homogenous materials where no foreign bodies are present in the mill stock, centrifugal separators for sand, excavator bucket teeth and bucket edge wear strips.

Alloy

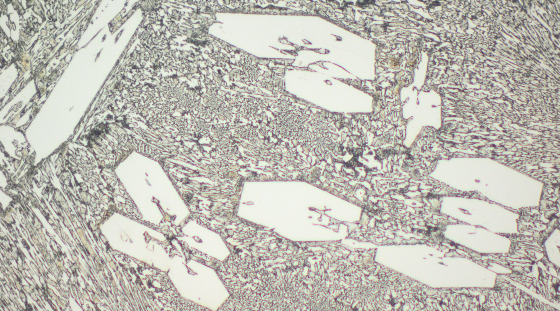

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID 100Mo

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).